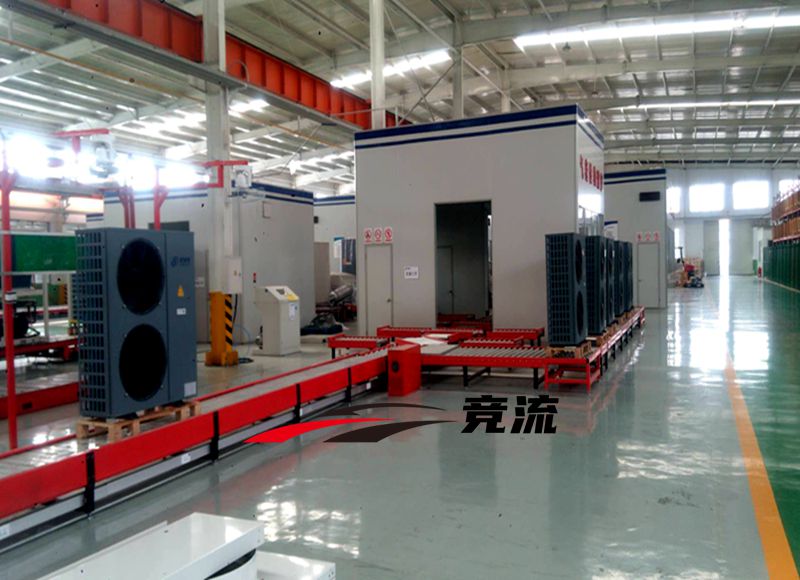

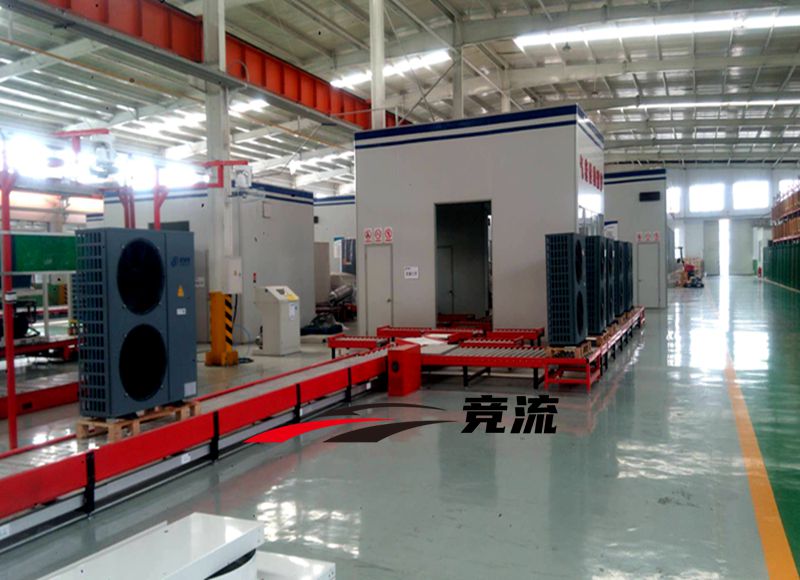

Air energy water heater assembly line

summary:

1. Automated conveying equipment

In the automated assembly line of air-energy water heaters, plate chain lines have become key transportation equipment for carrying heavy parts (such as enameled water tank liners and assembled semi-finished products) due to their high load bearing, wear resistance and stable transportation characteristics. Especially suitable for stations that require long-term stay or withstand external operations (such as welding and polishing). a. After-treatment and transportation of water tank liner After the inner container of the water tank is sintered with enamel (high temperature of 850-900℃), the temperature still reaches 100-200℃ and the weight reaches 50-150kg (different volume models). It needs to be transported to the cooling station and shell assembly station through plate chain lines. b. Rough assembly and transportation of the whole machine The plate chain wire can provide stable support when performing processes such as flange connection of the evaporator and the water tank, compressor lifting and other processes that require manual assistance or robot application of large external forces (such as axial force when tightening flange screws).

2. The core advantages of the air energy water heater assembly line

a. Efficiency improvement: A single assembly line can produce 500-800 units per day (about 200 units for traditional artificial lines), and the beat time is shortened to 3-5 minutes/unit. b. Stable quality: The pass rate of key processes (such as welding and leak detection) has been increased from 95% of labor to more than 99.5%, reducing after-sales costs. c. Flexible production: Through rapid type change (robot program switching, fixture replacement), 3-5 models can be switched within 1 hour.