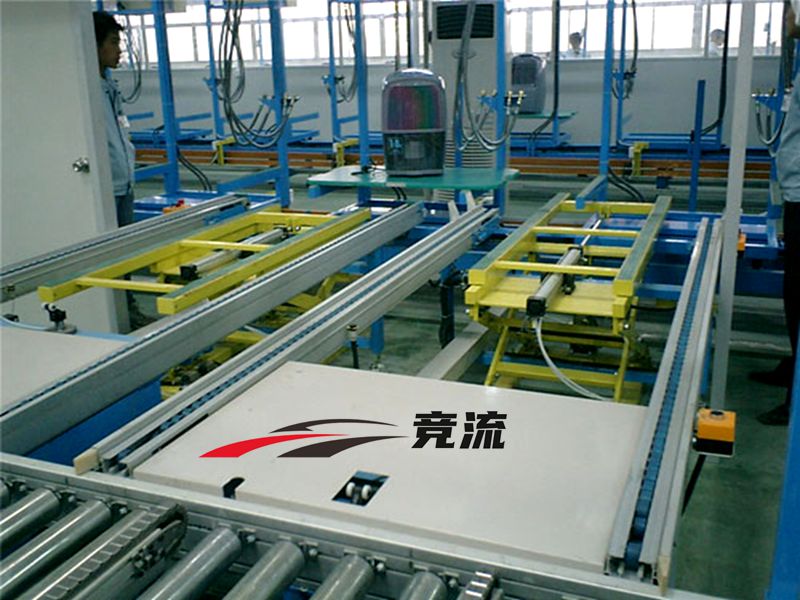

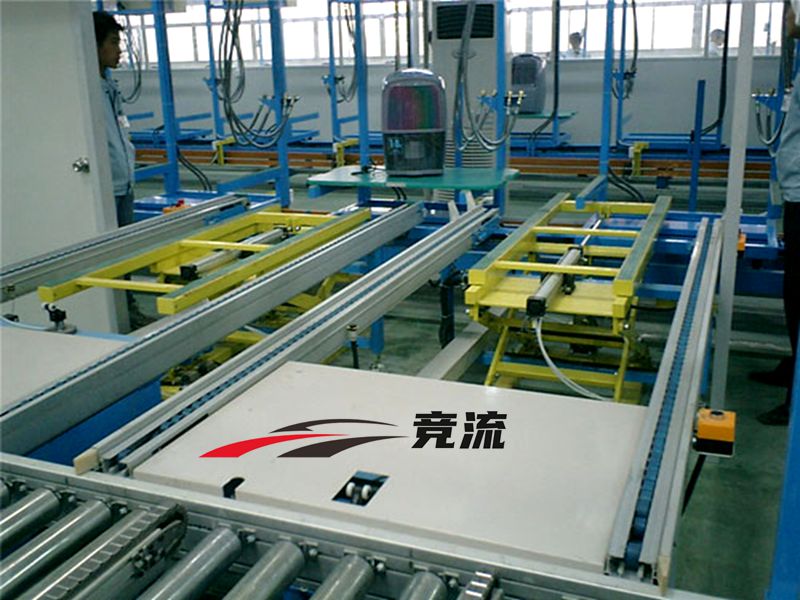

Air purifier assembly line

summary:

1. Automated conveying equipment

In the conveying system of the air purifier automated assembly line, double-speed chain conveyor and plate chain line are two highly targeted equipment, especially suitable for scenarios requiring precise positioning, synchronized beats, or carrying heavy parts. a. Double-speed chain transportation: The core assembly processes of air purifiers (such as fan installation, filter frame docking, and control panel assembly) rely on double-speed chains. For example, when installing a fan assembly (weighing 5-10kg), the tooling plate can be stably loaded and accurately stopped at the robot workstation, and automatically circulated after completing the screw locking. Suitable for the "multi-process, short-cycle" production characteristics of air purifiers (such as 8-12 processes required for single assembly), each workstation independently controls the dwell time of the tooling plate through a blocking mechanism to avoid the stagnation of the entire line due to the difference in time consumption of a certain process. b. Plate chain line transportation: The metal shell of the air purifier (weight 10-20kg) and the semi-finished products (including fans, filter screens, etc., weight 15-30kg) after the final assembly of the whole machine are mostly transported through plate chain lines to avoid deformation of belts or rollers due to insufficient load bearing. In the drying process (temperature 50-80℃) after coating the surface of the shell, the plate chain line can withstand high temperatures, and the metal chain plate is not easy to affect the transportation stability due to oil pollution.

2. The core advantages of the air purifier automated assembly line

a. Improved production efficiency: The production capacity of the manual line is about 500-800 units per shift, and the automated line can reach 1,500 - 3,000 units (depending on the configuration), and continuous production can be achieved for 24 hours a day. b. Strong product consistency: The operating accuracy of automated equipment can reach ±0.1mm (such as screw locking torque error ≤5%), avoiding assembly deviations caused by manual operation (such as poor filter sealing, fan installation tilt, etc.). c. Cost reduction and safety: Replace manual operations (such as handling heavy parts, contacting glue/sharp metal edges) to reduce the risk of work-related injuries. d. Flexible adaptation: Through PLC program adjustment, it can be quickly adapted to the production of air purifiers of different size (such as 100-500m³/h purification capacity) and different structures (such as vertical, wall-mounted), meeting the needs of multiple varieties and small batches.